|

Sprinklers,

structural documents and standpipes are the first factors to

be addressed during the design process. Sprinklers,

structural documents and standpipes are the first factors to

be addressed during the design process.

Determining the proper size and arrangement for

sprinkler/standpipe/fire pump systems in high-rise buildings

can be a straightforward task, but it requires establishing

the correct code and insurance requirements before beginning

the design process.

Codes and Standards

Large municipalities such as New York and Chicago have

maintained their own individual codes, which are quite

specific with respect to the design requirements,

arrangement and operations of sprinkler/standpipe/fire pump

systems. In contrast, smaller towns and cities have adopted,

and/or modified by amendment, one of the model codes, such

as the International Building Code.

Adding to the design uncertainty is the fact that all of the

codes reference varying editions of the pertinent NFPA

design standards regarding sprinklers, standpipes and fire

pump installations, and often recognize only some portions

of these standards and disregard others.

Insurance Requirements

The building owner’s insurance underwriter may wish to

review the proposed systems’ design to make recommendations

for the lowest rates of insurance. However, often the

additional costs of the recommendations vs. standard “code

minimum” system arrangements are so high as to become

unrecoverable against the resulting insurance premium

reduction over the normal life cycle of the building. The

choice to comply with these suggestions becomes a business

decision for the owner to make, resulting in a long lead

time and substantial cost impact to the project.

The engineer/designer serves the project and his own

design efforts well by determining the correct codes and

standard editions to follow, and to ask during the project’s

kick-off meeting for a current water flow test and the

owner’s insurance underwriter contact information. These

important items of direction and information influence the

design process, but tend to surface late in the project

development, and may cause aggravating changes and delays

unless requested early.

Sprinklers

Next, the engineer/designer must establish whether

sprinkler protection is to be provided for the project. When

a building occupancy involves situations where individuals

may not be fully conscious, ambulatory or readily capable of

taking action for self-preservation in a developing fire

event, sprinklers should be recommended, if not required by

code. These situations include actual physical lock-down for

criminal and psychiatric/dementia supervision;

incapacitation for illness, medical evaluation and drug

therapies; and sleeping individuals in hotels and living

residences. The current edition of the International

Building Code requires sprinklers in all high-rise

buildings. Sprinklers, if not required by the code, should

be recommended for residential occupancies in large

mixed-use buildings where occupancies of a higher fire

hazard—such as parking, restaurants, clubs, entertainment,

casinos, retail with inventory storage, etc.—are located

below the living/sleeping residences.

The modern residential sprinkler’s quick response and spray

pattern configuration can delay or prevent flashover, which

is the point in a fire event where a small developing fire

within a confined cubicle has heated and dried all the

latent moisture from the room and its contents. As a result,

everything within the cubicle ignites almost simultaneously,

producing an aggressive, thick, choking black smoke that is

driven rapidly by the high heat into distant parts of the

building. In contrast, smoke developed from a fire that has

activated one or more modern sprinklers is thin, grey, less

aggressive and ultimately more survivable to those who may

come into contact with it.

Design Tasks and Information

The engineer/designer must examine the

architectural/structural documents for information to

confirm several things:

- The highest stairwell-accessible, normally occupied

floor and its elevation above grade entry level;

- The elevation of the highest required sprinkler

system;

- Intended location and adequate room size for the

necessary fire pump equipment;

- The number of required egress stairwells, and that

the size of stairwell interiors provides adequate room

for fire dept. valves on standpipes. The stairwells

should also leave room for the inclusion of necessary

express risers and/or combined sprinkler/standpipe and

drain risers without encroachment into the egress

turn-around radius at each floor or intermediate

landing;

- There is adequate space and headroom (minimum 7' 0")

for system control valves.

After this, the engineer/designer must examine the code

requirements and speak with the Authority Having

Jurisdiction (AHJ) to confirm and determine:

- The residual flow and pressure required at the most

remote standpipe or combined sprinkler/standpipe;

- The Class of standpipe protection necessary (I, II

or III) and any additional appurtenances for standpipe

connections and equipment the fire department may

currently request;

- The maximum pressure allowed for the system at the

churn conditions;

- If the fire pump is required to be connected to an

emergency source of power (such as a diesel-driven

emergency generator set) or secondary source of power

from a separate electrical sub-station;

- The desired location of the standpipe and fire

department connection within the stairwell enclosure,

either on the main or intermediate landing.

Standpipes

Most

codes establish the flow rate for the fire pump or pumps

directly, or by referring to an NFPA 14 edition, based on

the number of required standpipes. Generally, it’s 500 gpm

for the first standpipe and 250 gpm for each additional

standpipe, to a maximum of 1,250 to 1,500 gpm, depending on

code or standard edition referenced. Most

codes establish the flow rate for the fire pump or pumps

directly, or by referring to an NFPA 14 edition, based on

the number of required standpipes. Generally, it’s 500 gpm

for the first standpipe and 250 gpm for each additional

standpipe, to a maximum of 1,250 to 1,500 gpm, depending on

code or standard edition referenced.

The number of required standpipes may be equal to the

number of required egress stairwells (one in each required

stairwell) or may be dictated by coverage of all areas of

all floor plans—from standpipes located within the reach of

a specified length of hose and water stream discharge of a

nozzle, directed into the most remote rooms.

Placement of standpipes should begin with one in each

required egress stairwell, and if additional ones are

required to meet the length of hose and stream coverage

requirement, they are placed outside the stairwells.

The majority of high-rise buildings are used for office

and residential occupancy, and both these occupancy

classifications are light hazard sprinkler demands, and

therefore do not represent the most hydraulically demanding

sprinkler requirement. Ordinary hazard sprinkler

demands—such as those present at cooling towers; mechanical,

electrical or elevator machine rooms located at the top of

the building; or larger areas of ordinary hazard occupancies

below the tower portion of the building—should be identified

and evaluated as more demanding factors for sizing the fire

pump.

The hydraulically worst-case sprinkler demand is usually

added to the NFPA 14 standpipe demand for pump sizing,

although some codes recognize that not more than two to

three standpipes will be used by firefighting personnel in a

single fire event for mop-up operations in a fully

sprinklered building. Therefore, some codes permit sizing of

the fire pump to be half the gross standpipe demand, plus

the worst-case sprinkler demand.

Part II of this article will discuss: The residual

pressures required at the top outlets; the arrangement and

sizes of standpipes, mains and express risers that are to be

specified by the engineer/designer; series and parallel

pumping; drives; emergency sources of power and means to

reduce churn; and residual pressures in multiple pumping

systems.

SIDEBAR: Design Exception: Code May Provide for

Standpipe/Sprinkler Systems Without a Fire Pump

Design

situations that have a high residual water-main pressure and

are 5-8 stories in height may avoid the inclusion of a fire

pump with the sprinkler/standpipe system altogether. If the

street pressure satisfies the hydraulic demand requirements

for the sprinkler system, a fire pump is not necessary for

the sprinkler system or standpipe. This exception is based

on the building being completely sprinklered by an NFPA 13

system. The standpipe pressure can be satisfied by the fire

department pumper connecting to the fire department

connection for the systems. The Class I standpipe

connections are considered for use by the fire department

only. Design

situations that have a high residual water-main pressure and

are 5-8 stories in height may avoid the inclusion of a fire

pump with the sprinkler/standpipe system altogether. If the

street pressure satisfies the hydraulic demand requirements

for the sprinkler system, a fire pump is not necessary for

the sprinkler system or standpipe. This exception is based

on the building being completely sprinklered by an NFPA 13

system. The standpipe pressure can be satisfied by the fire

department pumper connecting to the fire department

connection for the systems. The Class I standpipe

connections are considered for use by the fire department

only.

Projects in this category also are quite often

budget-sensitive, and may further avoid costs by having the

base of the standpipe and sprinkler risers supervised and

controlled with outside screw and yoke gates. These gates

are chained and pad-locked in the open position and use an

alarm check valve to drive an exterior water motor gong,

which sounds the necessary alarm required when a single

sprinkler operates. This design avoids the need for an

electronic fire alarm system to supervise tamper switches

and water flow, if such a system is not otherwise required

by the code.

Equally important, this design effectively makes the

entire building a single sprinkler zone, which is permitted

to a maximum of 52,000 sq. ft. by NFPA 13, but leaves

specific drawbacks with respect to the maintenance time of

replacing a sprinkler that has activated or become damaged.

All levels above the damaged or activated sprinkler will

need to be drained down to permit maintenance at that level

needing repair, and then refilled when repairs are

completed. This removes sprinkler protection for the

duration of the repairs from many unaffected levels above,

when the occurrence is at a lower level of the building. If

the project is strictly residential, where unit layouts are

not normally revised frequently, this situation may be okay,

but prove difficult if it is an office occupancy or offices

with residences above as office layouts are typically

revised with each tenant change, leaving the floors above

without sprinkler protection. Regardless of occupancy,

buildings of more than 10 stories are better served with

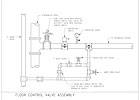

each floor supervised and controlled as a separate sprinkler

zone, as represented by Figure 1 on page 20.

Robert H. Thompson, CIPE

Robert H. Thompson, CIPE, has nearly 40 years of

plumbing and fire protection design experience and

has led design teams of prestigious consulting

engineering firms. He is the plumbing and fire

protection director at Mehandes Engineering P.C.,

a MEP/FP engineering firm that specializes in

commercial and high-rise residential projects.

Thompson pioneered the design of centralized hot

water supply and recirculation systems for high-rise

buildings that is the arrangement of choice in the

Chicago area. His e-mail address is

rthompson@mehandeseng.com.

|